|

Historic Lotus Register | News |

|---|

The Historic Lotus Register Events web page has been updated with dates for 2026. Some dates are provisional, and more details will appear in the Winter 2025 issue of Historic Lotus.

The Historic Lotus Register had a stand (3-340) at the Classic Motor Show, which took place at the NEC from 7th- 9th November.

Cars on the stand included a Type 14 Elite, Lotus 47GT fresh from a restoration at Classic Team Lotus, future Team Lotus driver Alan Stacey's Lotus VI, Lotus 69 (F3), the 1956 Monza record breaking Lotus Eleven (driven by Moss and Fraser), and a modern Lotus Emira, in line with the organisers' theme 'Best of Both Worlds'.

|

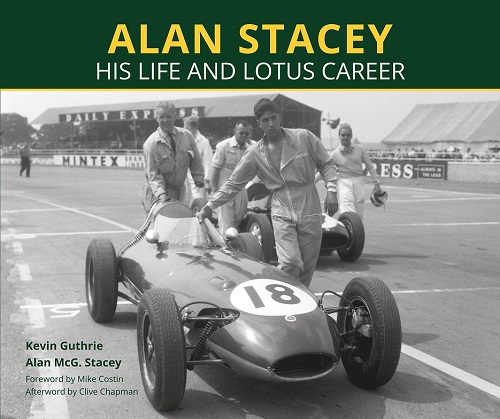

“Alan Stacey – His Life and Lotus Career” chronicles Stacey’s journey from early drives in his Lotus VI—recently displayed on the HLR stand at the Classic Motor Show—to his ascent as a Team Lotus driver, competing at Le Mans and in Formula 1.

The book includes excerpts from Alan's notebooks and photograph albums, and contributions from his siblings, fellow Lotus driver Peter Ashdown, Team Lotus' Maurice Levy, and Ian Scott-Watson. It may be pre-ordered, with despatch planned for late February, 2026.

|

“Great Auclum National Speed Hill Climb 1938-1974” is not specifically about Lotus, but covers the period when Colin Chapman was starting out in motorsport. The book is the result of 30 years of research by its author, Stephen Lovegrove, and is limited to 200 copies. It may be pre-ordered, with release planned for 12th December, 2025.

|

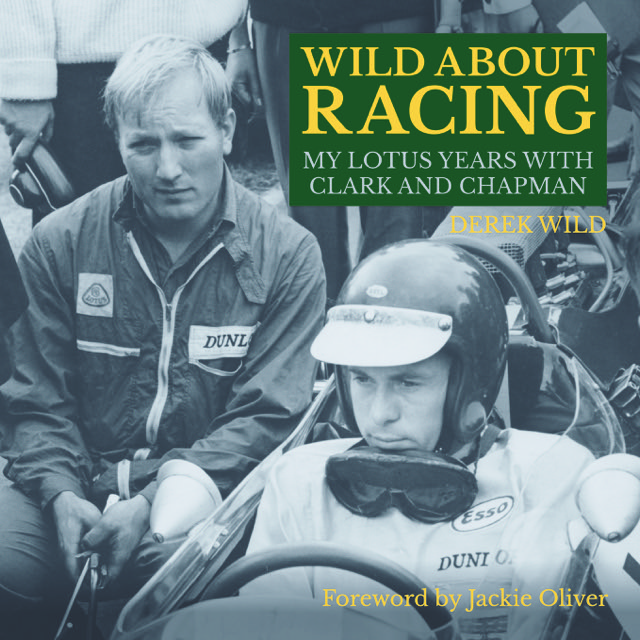

“Wild About Racing” was originally launched at the Jim Clark Motorsport Museum in June 2024, but has recently been reprinted in a softback edition. It offers a personal account by Derek Wild of his years at Lotus, highlighted by the 1963 Formula 1 World Championship victory with Jim Clark. Illustrated with behind-the-scenes photographs taken by Derek himself, the book captures the spirit and camaraderie of the era. The Foreword is by Jackie Oliver—another driver Derek worked closely with.

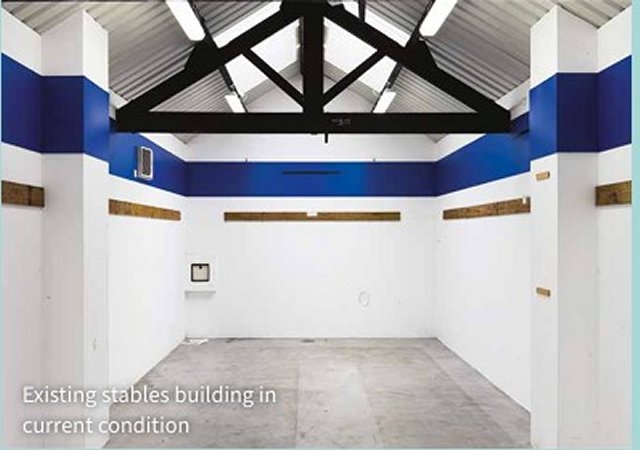

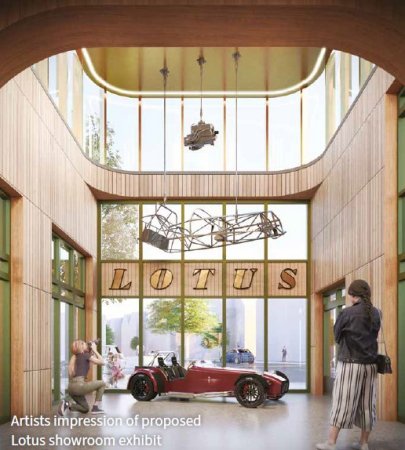

Colin Chapman's first car was built in a garage behind Hazel Williams' family home. He then teamed up with the Allen brothers, who had use of a workshop at their parents' house, before taking over some of the outbuildings adjacent to a pub owned by his father. Over the next few years these were adapted and extended with the addition of a small showroom and office building, before Lotus moved to a purpose-built factory in Cheshunt. The old Lotus works and showroom on Tottenham Lane, Hornsey have, until recently, been used by a builders' merchant. The site is now unoccupied, and a brownfield mixed-use development has been proposed by Fifth-State.

The development proposed would include use of the Showroom, and the stables and store-rooms used by Lotus, as a community cafe, with exhibits to celebrate the Lotus heritage. There would also be a public square, and student accomodation with a ground floor industrial area. Most of this would be on the land at the rear of the Lotus site, extending alongisde the railway lines.

More details of the original and updated proposals can be seen here, and here (June update), and feedback can be expressed at thelotusbuilding.com, where you can also register to be informed of updates.

Nigel Allen passed away at the end of February at hospital in Dorset after a recent illness. Nigel was 93 years old.

He was the last surviving member of the original ‘’core’’ Lotus gang of Colin Chapman, Hazel Williams and Michael Allen. With his brother Michael he probably did more than anybody else to set Colin and Hazel Chapman on their way to the formation of Lotus Engineering Ltd. and the subsequent models and company that we all know it today. Without the Allen brother’s skills, tools, garage and enthusiasm (not forgetting their mother Jennie Allen’s tea and biscuits!) the Lotus Mark III would not have been constructed and become so successful in 1951.

After his Lotus contributions, as well as practising as a dentist, Nigel went on to develop and patent high precision engineering tools and equipment, including high speed dental drills.

The HLR wish to send condolences to Nigel’s children, Jill, Deryn, Simon and Samantha, and their families.

There is a full obituary of Nigel in Historic Lotus, issue 120.

There is an article about the Allen brothers' involvement with Colin Chapman here, and an account of Nigel's racing experiences.

| Top photo - The newly-restored Lotus Mk IV at Brooklands in April 2003 with Nigel Allen at the wheel. |

| Lower photo - Nigel and Michael Allen in the Lotus Mark III - Castle Combe 2003. |

The 'For Sale' page has been updated - it will now include the advertisements from the current issue of Historic Lotus.

The Federation of British Historic Vehicle Clubs (FBHVC) has issued a Press Release, which members might find useful to read, regarding the introduction of E10 petrol and its use in classic cars.

The full article is available on the FBHVC website here, or can be downloaded here. Parts of it are reproduced below.

After an extensive consultation process, the Department for Transport has introduced legislation to mandate E10 petrol as the standard 95-octane petrol grade in Great Britain from 1 September 2021 (in Northern Ireland, this will happen in early 2022). They will also require the higher-octane 97+ 'Super' grades to remain E5 to provide protection for owners of older vehicles. This product will be designated as the 'Protection' grade. The change in fuel applies to petrol only. Diesel fuel will not be changing. Petrol pumps now show new labels designating the grade, the maximum ethanol content and an advisory cautionary notice. Other information regarding the introduction of E10 petrol may also be provided by fuel retailers such as the 'Know your Fuel' sticker. The Federation recommends that all vehicles produced before 2000 and some vehicles from the early 2000s that are considered non-compatible with E10 - should use the Super E5 Protection grade where the Ethanol content is limited to a maximum of 5%.

Some historic vehicles use materials in the fuel systems that are damaged by ethanol. These include some cork, shellac, epoxy resins, nylon, polyurethane and glass-fibre reinforced polyesters. In later cars these have largely been replaced with paper gaskets, Teflon, polyethylene and polypropylene which are all unaffected by ethanol. Very old leather gaskets and seals are also resistant to ethanol.

As the ethanol molecule is smaller and more polar than conventional petrol components, there is a lower energy barrier for ethanol to diffuse into elastomer materials. When exposed to petrol/ethanol blends these materials will swell and soften, resulting in a weakening of the elastomer structure. On drying out they can shrink and crack resulting in fuel leaks.

If your fuel system has old hoses or any degradation of components, then ethanol may appear to advance these problems very quickly. You may experience leaks or fuel 'sweating' from fuel lines. Some fuel tank repair coatings have been found to breakdown and clog fuel systems, although there are plenty of ethanol resistant products on the market.

Ethanol contains approximately 35% oxygen by weight and will therefore result in fuel mixture enleanment when blended into petrol. Petrol containing 10% ethanol for example, would result in a mixture-leaning effect equivalent to approximately 2.6%, which may be felt as a power loss, driveability issues (hesitations, flat spots, stalling), but also could contribute to slightly hotter running. Adjusting mixture strength (enrichment) to counter this problem is advised to maintain performance, driveability and protect the engine from overheating and knock at high loads.

Ethanol has increased acidity, conductivity and inorganic chloride content when compared to conventional petrol which is typically pH neutral. Ethanol can cause corrosion and tarnishing of metal components under certain conditions. These characteristics are controlled in the ethanol used to blend E5 and E10 European and UK petrol by the ethanol fuel specification BS EN15376 in order to help limit corrosion.

Some aftermarket ethanol compatibility additives claim complete protection for operating historic and classic vehicles on E10 petrol. The FBHVC is not aware of, or has tested any additives that claim complete fuel system protection with respect to elastomer and gasket materials for use with E10 petrol. The FBHVC therefore recommends that elastomer and gasket materials are replaced with ethanol compatible materials before operation on E10 petrol.

However, corrosion inhibitor additives can be very effective in controlling ethanol derived corrosion and are recommended to be added to ethanol in the BS EN15376 standard. It is not clear if corrosion inhibitors are universally added to ethanol for E5 and E10 blending so as an additional precaution it is recommended that aftermarket corrosion inhibitor additives are added to E5 and E10 petrol.

These aftermarket ethanol corrosion inhibitor additives often called ethanol compatibility additives are usually combined with a metallic valve recession additive (VSR) and sometimes an octane booster and have been found to provide good protection against metal corrosion in historic and classic vehicle fuel systems.